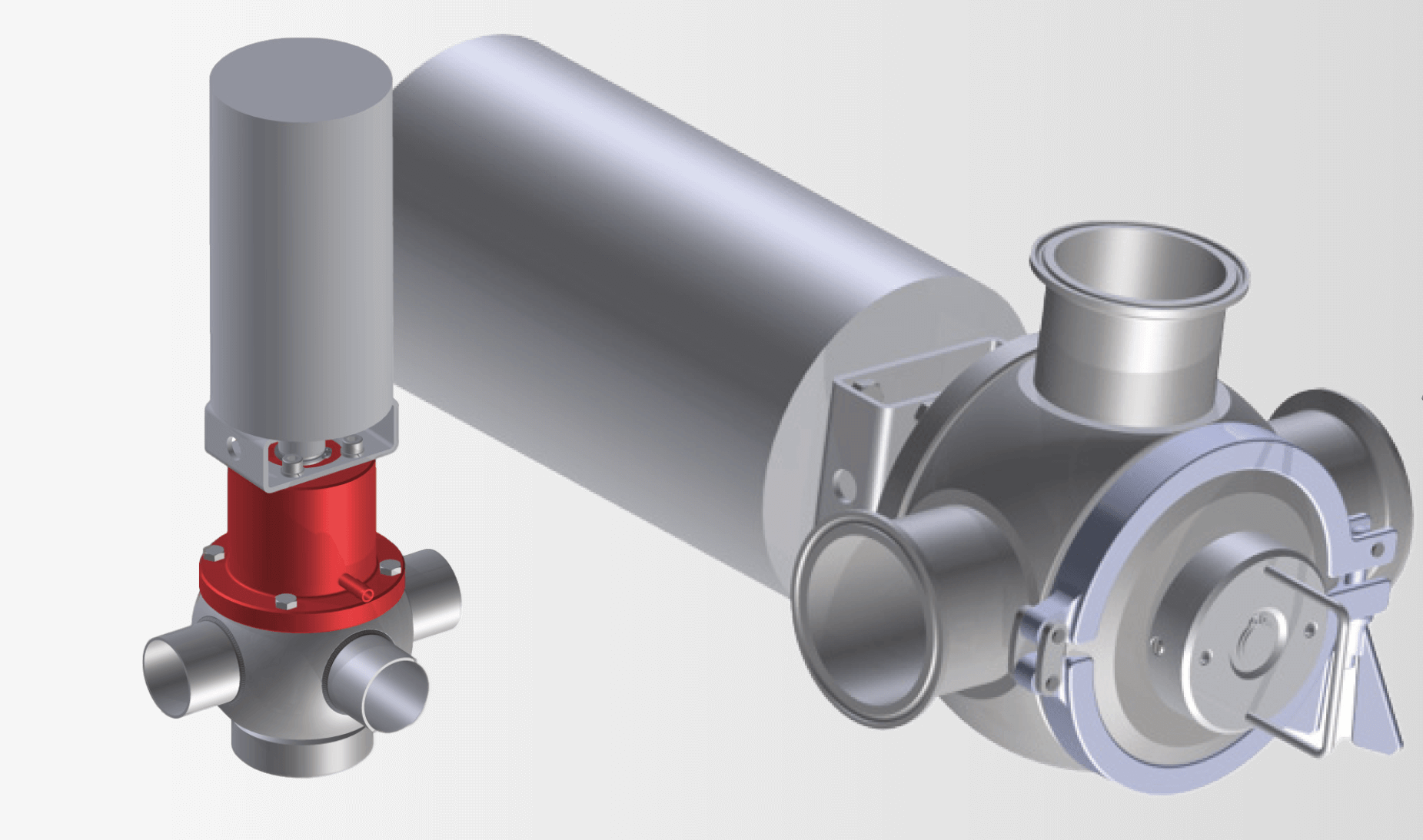

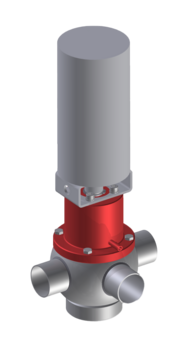

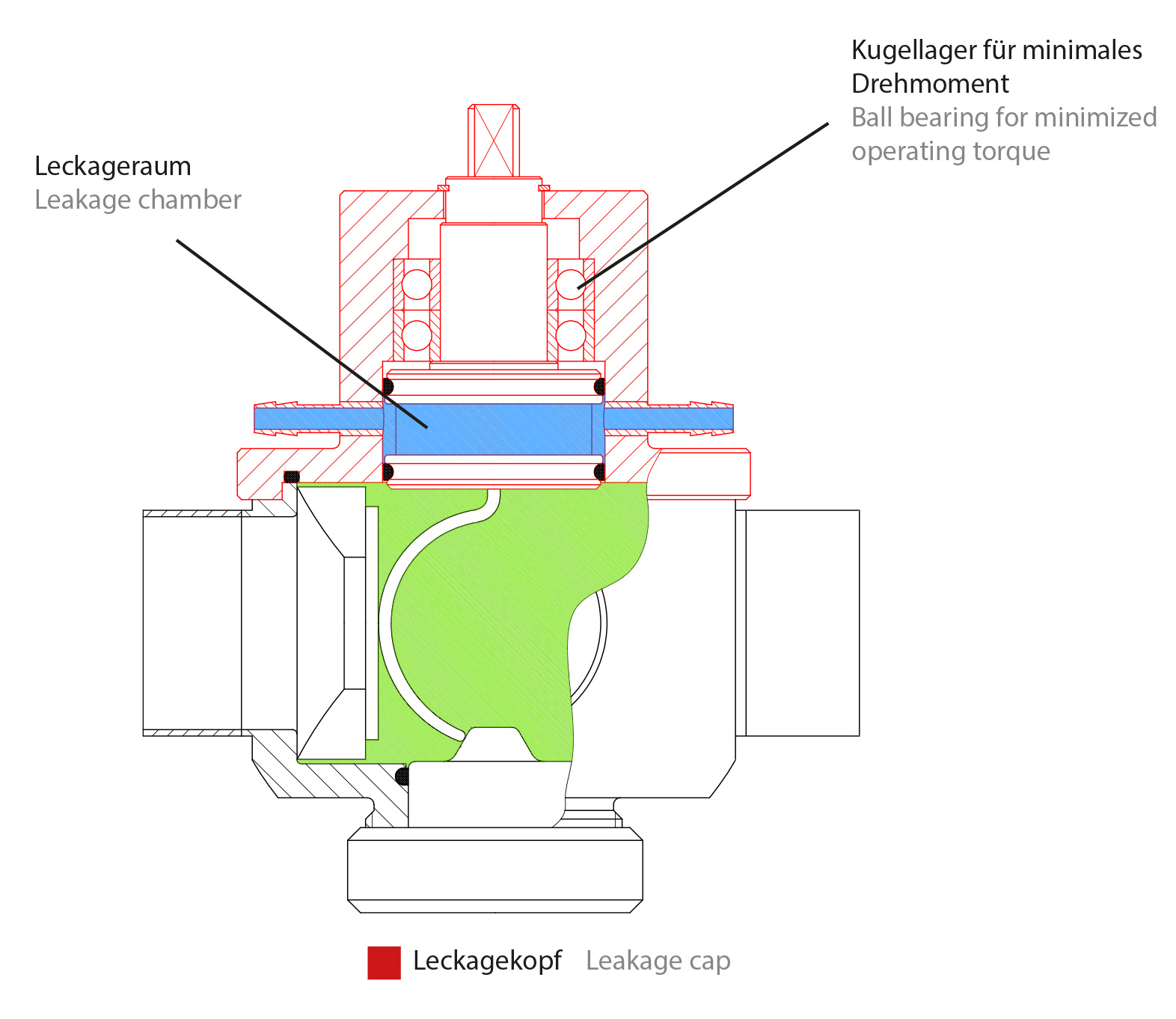

For maxiumum product safety LIAG® free flow shutter valves are available with a leakage monitoring System of the only dynamic O-ring. This specific design identifies possibile wearing defects of the seal and prevents any contamination from the outside Environment.

The special designed leakage chamber can act as a steam barrier or offer monitoring via means of a level conductor control (dilution of glycerine).

The pivoting axle is supported with a ball-bearing shaft for increased stability and less required operating torque compared with the standard shutter valve.

Features

- Maxiumum product safety for aseptic processes

- No contamination from the outside Environment by as a result of excessive wearing or a defective stem O-ring seal

- Quick acting valve due to low operating torque requirements (ball-bearing supported main shaft)

- Able to be retrofit to shutter valves

- DIN DN40 – DN 80 / SMS 38 – 76 / Inch 1,5"– 3"